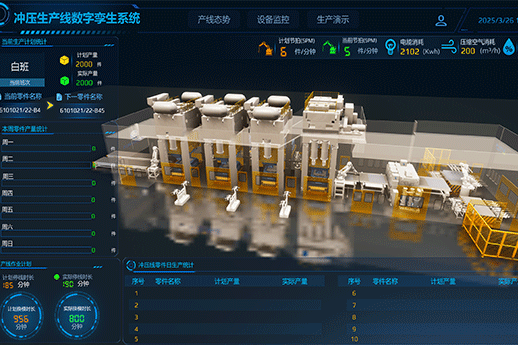

Aotto Powers Smart Stamping Upgrade for XXX Automotive Manufacturer with BDE and AI Technology

Aotto has successfully deployed its Betriebsdatenerfassung (BDE) data acquisition platform at the stamping workshop of an automotive manufacturer. The solution has enabled real-time data collection and cloud-based analysis across multiple production sites, significantly improving operational efficiency across multiple sites.

Challenge

Prior to implementation, the client faced data distortion issues caused by a hierarchical reporting structure, preventing headquarters from accessing accurate production data and identifying bottlenecks in a timely manner.

Aotto’s BDE Solution

• 300+ data points—including equipment status, process parameters, and downtime notifications—from multiple regional plants have been collected and synchronized to the cloud within seconds, achieving a 50% increase in response efficiency.

• By leveraging Statistical Process Control (SPC), the system has improved alert accuracy by 10% and reduced troubleshooting time by 87.5% (from 2 hours to 15 minutes).

• Key metrics such as OEE (Overall Equipment Effectiveness) and CPK (Process Capability Index) are monitored in real-time, resulting in a 40% increase in resource allocation efficiency.

Project Results

Leveraging 20 years of experience in stamping automation and proprietary data integration technology, Aotto’s BDE platform has delivered:

• Direct production data access to headquarters

• Eliminated manual reporting and ensured data accuracy

• 70% improvement in anomaly response time

Building on the success of the BDE system, Aotto has collaborated with the client to implement AI-based visual safety monitoring across production facilities.

AI-Powered Safety System: Enhancing Workshop Safety

1.Real-time Monitoring

20+ Channel cameras and deep learning algorithms now detect unauthorized access to hazardous zones and automatically issue alerts within milliseconds. Extended personnel presence automatically triggers warnings to safety supervisors.

2.Violation Recognition

The system identifies unsafe behaviors—such as not wearing helmets or crossing safety lines—and activates audio-visual alarms, with simultaneous alerts sent to management terminals.

3.Cost-effective Deployment

Supports integration with existing camera infrastructure, enabling full deployment and adaptive calibration in under five minutes.

Looking Ahead

Aotto and its client are now exploring automation upgrades at the end of the stamping line, including robotic bin loading and automated inspection, to further optimize production flow.

Moving forward, Aotto remains committed to advancing the industrial application of big data and AI, delivering smarter, more reliable digital solutions for manufacturing excellence.

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.