Aotto Launches New Flexible Barrier Series

In today’s fast-paced industrial environment, are you facing these common challenges?

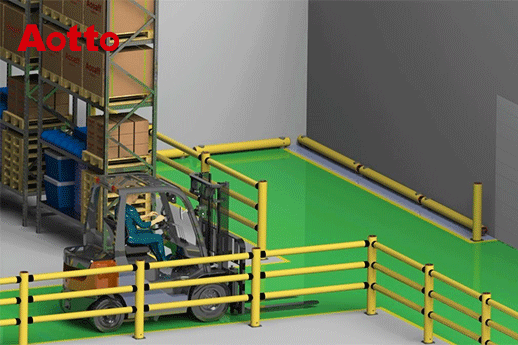

● Mixed pedestrian and vehicle traffic, leading to uncontrolled safety risks

● Loading docks lack proper isolation

● Frequent collisions with columns, corners, and edges, driving up maintenance costs

● Traditional barriers that fail to adapt to dynamic site layouts

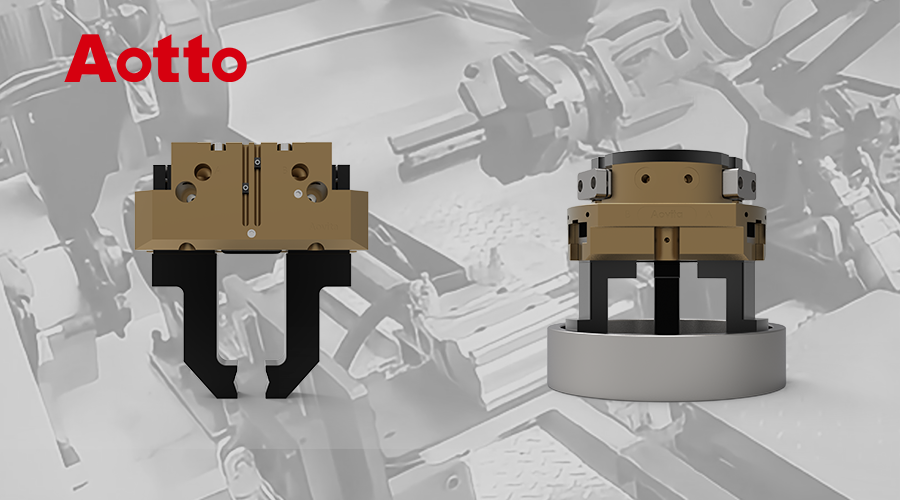

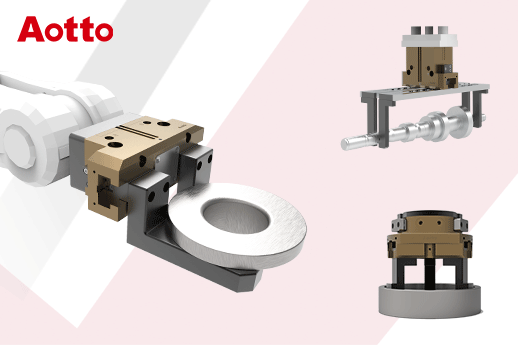

Aovita Robotic Grippers – Precision Grip for Smarter Automation

Robotic grippers are key components in any automated system. They help hold, move, and put together different workpieces. They also affect the speed, accuracy, and stability of your production line. At Aotto, we develop grippers that deliver strong gripping force, reliable performance, and high adaptability.

The Aovita series pneumatic robotic grippers include two major types of grippers:

-

2-finger parallel grippers

-

3-finger centric grippers

With a load capacity of up to 70 kg, these grippers are suitable for handling both lightweight and heavy components. They are widely used by automation equipment manufacturers and industrial robot integrators across industries such as automotive, machining, new energy, casting, and packaging.

Safety Production Month – Building a Safe Production Environment

Every June marks China’s National Safety Production Month. For industrial enterprises, industrial safety and workplace safety are always the top priorities. Here, we share practical measures and ideas to foster a safer production environment during this month and beyond.

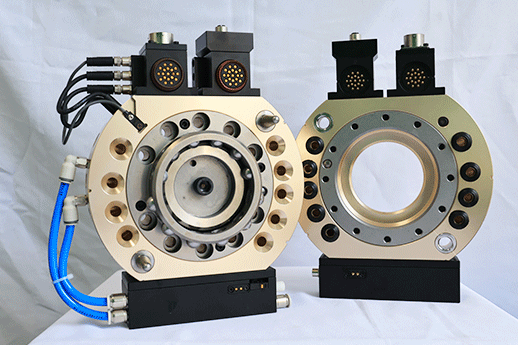

Top 5 Features of a Reliable Industrial Robotic Tool Changer | Aotto 2025 Guide

Industrial robotic tool changers help machines switch tools quickly and safely. But not all tool changers are the same. Let’s break down the 5 most important features to check before buying one.

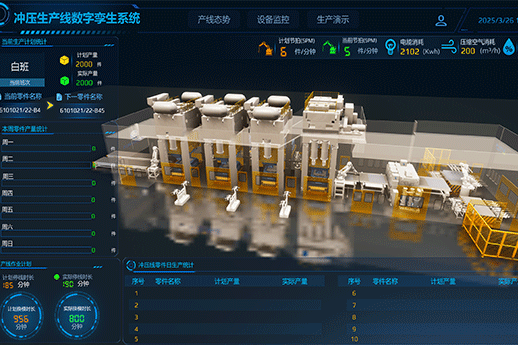

Aotto Powers Smart Stamping Upgrade for XXX Automotive Manufacturer with BDE and AI Technology

Aotto has successfully deployed its Betriebsdatenerfassung (BDE) data acquisition platform at the stamping workshop of an automotive manufacturer. The solution has enabled real-time data collection and cloud-based analysis across multiple production sites, significantly improving operational efficiency across multiple sites.

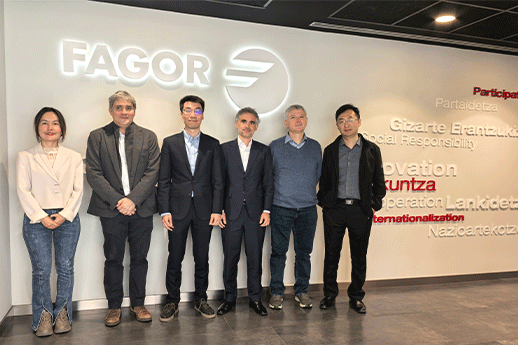

Aotto Explores Collaboration with Leading European Automotive Manufacturers

From April 7 to 12, 2025, a delegation led by Mr. Puxuan He, Deputy General Manager of Aotto, visited several renowned automotive and equipment manufacturing companies across Europe. T This six-day exchange aimed to strengthen collaboration in intelligent manufacturing. All parties shared a commitment to innovation, technical exchange, and mutual success — laying a solid foundation for delivering more advanced and efficient automation solutions to global customers.

Aotto at Hannover Messe 2025 | Moving Towards Global Market with Innovation Drive

From March 31 to April 4, the Hannover Messe 2025 was successfully held in Germany. Aotto proudly took part in this world-renowned industrial fair, showcasing a lineup of innovative solutions while engaging with global industry experts, customers, and partners. Through this platform, We demonstrated its growing technological strength and market potential in automation, industrial safety, and robotic end-effectors.

Aotto Flexible Impact Barrier: For Forklift Safety in Warehouses

In modern warehousing and manufacturing, collisions frequently occur in workplaces with multiple forklifts operate simultaneously. These incidents will cause damage to personnel, equipment, and shelves, leading to costly repairs and production interruptions. Businesses urgently need an efficient, durable, and safe protection solution—Aotto Flexible Guardrails, a tailored solution designed to meet this demand.

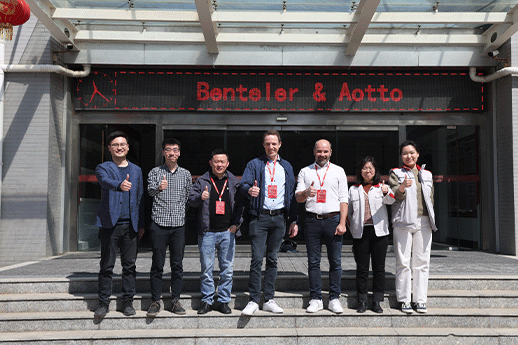

BENTELER Delegation Visits Aotto to Explore Collaboration Opportunities

Recently, a delegation from BENTELER, a globally renowned automotive parts manufacturer, visited Aotto to gain deeper insights into its technological capabilities, product quality, and production capacity, aiming to explore potential collaboration opportunities.

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.