Aotto Robotic Tool Changer: Revolutionizing Industrial Automation

In the realm of industrial automation, the Robotic Tool Changer (also known as an Automatic Quick Changer or Tool Changer) has emerged as a pivotal component in enhancing the flexibility and efficiency of robotic systems. These devices, integral to the performance of high-end industrial robots, facilitate the swift interchangeability of various end-effectors, enabling robots to undertake a multitude of tasks with precision and speed.

What is a Robotic Tool Changer?

Robotic Tool Changer is a sophisticated interface that connects the robot arm to its end-effector, allowing for a seamless transition between different tools. This capability is crucial in applications such as automatic welding, material handling, assembly, inspection, and packaging, where the ability to quickly switch tools significantly reduces downtime and enhances production throughput.

Key Features of Robotic Tool Changers

-

Speed and Efficiency: With an Automatic tool adapter, tool swaps can be completed in mere seconds, drastically reducing the time typically associated with manual changes.

-

Enhanced Flexibility: By employing multiple end-effectors, a single robot can perform varied operations, which increases the system's adaptability to different manufacturing needs.

-

Reduced Complexity: Utilizing specialized tools for specific functions rather than bulky, multifunctional end-effectors simplifies operations and maintenance.

-

High Reliability: The design of Tool Changer ensures robust and dependable operation, with features like hydraulic cylinders and guiding mechanisms that enhance the stability and longevity of the connection.

Applications in Industry

The versatility of Robotic Tool Changers makes them indispensable in numerous industrial settings. They are extensively used in processes such as point welding, arc welding, material lifting, stamping, deburring, and more. Their ability to quickly change tools not only improves the operational efficiency but also extends the functional scope of robotic arms.

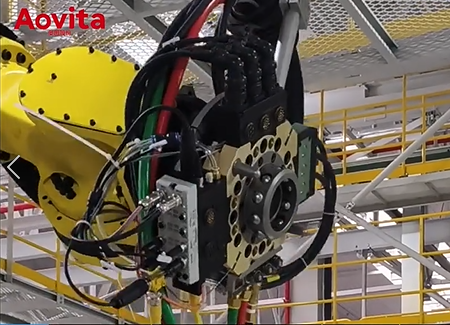

Structural Design and Functionality

Robotic Tool Changers consist of two primary components: the robot side (Master Side) and the tool side (Tool Side). The Master Side is attached to the robot's forearm, while the Tool Side is mounted on the end-effector, such as a welding gun or gripper. This setup allows for the transmission of electric signals, fluids, gases, and even data between the robot and its end-effectors, ensuring that each tool performs optimally during its operation.

The integration of a Robotic Tool Changer into industrial robots significantly boosts the productivity and flexibility of manufacturing lines. By enabling quick and reliable tool changes, these devices allow robots to perform a diverse array of tasks efficiently, making them a cornerstone of modern automated production systems. Whether it's through an Automatic Quick Changer or Tool Changer, the benefits of enhanced speed, reduced downtime, and increased versatility are clear, marking a transformative step forward in industrial automation technology.

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.