Pneumatic grippers: For efficient and precise workpiece gripping

Gripper, installed at the end of the industrial robot arm, is one of the indispensable equipments in industrial automation, which can realize all kinds of workpiece gripping, handling and assembling operations with the industrial robot arm, and is widely used in stamping, machining, automotive parts and other industries.

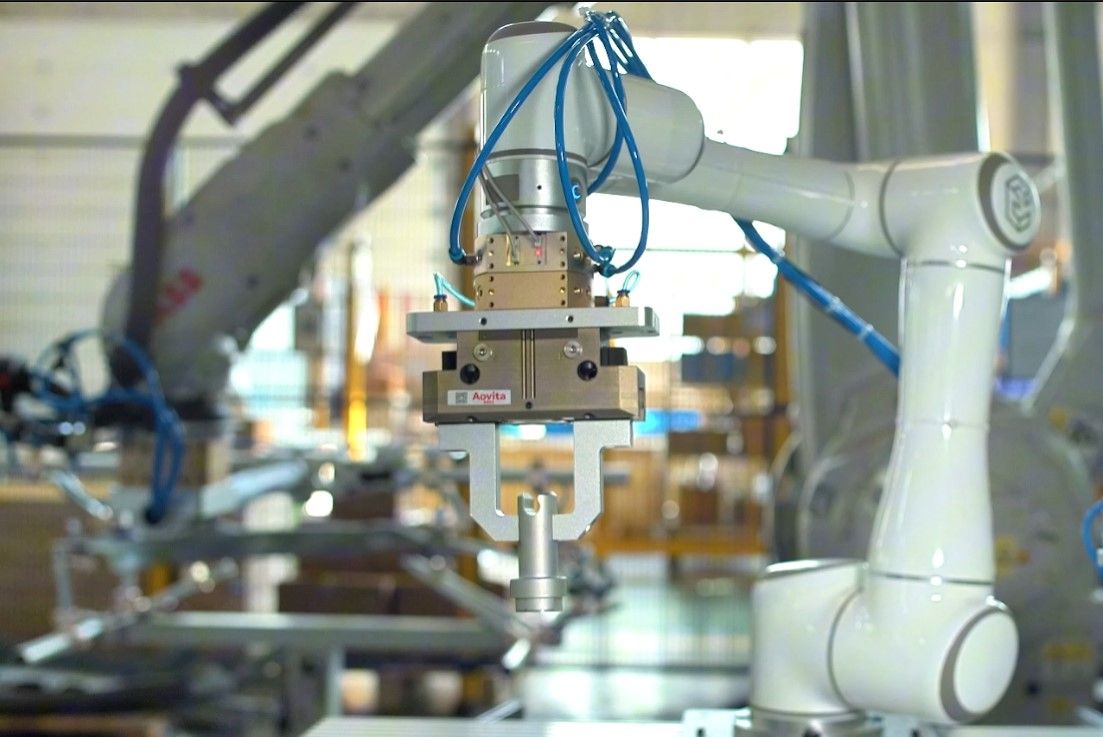

Aotto pneumatic gripper

Aotto grippers are pneumatic versions and are available in two series: PET two-finger parallel grippersand PST three-finger centering grippers

Working Principle

Aotto pneumatic gripper uses compressed air as the power source. The air pressure is converted into mechanical energy through a cylinder, allowing the gripper to open or close quickly.

Function

- Quick gripping: Pneumatic drive for fast gripping and releasing, improving the production pace.

- Precise positioning: Ensure the stability of the workpiece during machining or handling, reducing deviations.

- Versatility: Flexibility to adapt to different shapes and sizes of workpieces.

Advantages

High Usability: Pneumatic drive enables quick gripping and flexible movement; the main body is made from high-strength, lightweight materials to reduce additional load; multiple installation and air connection options allow for efficient setup.

Safety and Reliability: Compact design and sturdy structure ensure stable gripping and minimize operational interference; features such as air-loss self-locking or pressure-holding self-locking enhance safety.

Cost-Effectiveness: In-house manufacturing of core components ensures high precision; installation holes are compatible with most common grippers on the market, ensuring interchangeability.

Technical points and components of major concern

When selecting grippers, the following technical points are usually of interest:

- Gripping Force: The max. gripping force of the jaws and the applicable range, which ensures that it can safely and securely grip workpieces of different weights.

- Response Time: Quick gripping and releasing times help to increase productivity.

- Compatibility: Whether the gripper is compatible with existing robotic arms for easy integration.

- Self-Locking function: Whether it has air cut-off self-locking or pressure-preserving self-locking function to prevent workpieces from falling during a loss of air supply, thus protecting equipment, assets, and personnel safety.

- Positioning Accuracy: Stability under heavy loads and repeat positioning accuracy to ensure the precision of workpieces during processing or transport.

With its outstanding performance and versatile features, Aotto pneumatic gripper is an ideal choice for modern industrial automation. By choosing Aotto gripper, you will experience a more efficient and safer production process.

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.