Flexible barrier: "Safety is an investment, not a cost."

In modern warehouse management, safety is always a top priority. With the popularization of automation and efficient logistics operations, it has become even more important to protect the safety of personnel, equipment and goods. Flexible barriers, as an emerging safety solution, are gradually becoming the new favorite of the warehousing industry.

What is Flexible barriers?

Flexible barriers, also called impact barrier and impact guardrail, is a kind of safety protection product with polymer material (such as polyurethane or other engineering plastics) as the main structure. Compared to traditional rigid metal guardrails, flexible barriers offer superior cushioning performance, absorbing the impact force and bouncing back to its initial state after the collision is over, thus minimizing damage to the vehicle, the cargo, and the barrier itself. These features make them ideal for logistics and warehousing environments where there are frequent equipment operations and potential collision scenarios.

Advantages of Aotto Flexible Barriers:

- Efficient Energy Absorption and Shock Absorption

Aosaff Flexible Barriers are made of polymer materials that absorb energy through deformation when subjected to impact, spreading the impact force over a wider area and reducing secondary injuries to people, equipment and shelves.

- Reduced Maintenance Costs

Compared to traditional steel guardrails, flexible barriers can bounce back to the initial state after the collision is over, which means lower maintenance and replacement costs. At the same time, equipment damage, downtime and loss of goods due to vehicle collisions can also be reduced by optimizing the safety design.

- Modular Design

Aosaff Flexible Barriers feature a modular split design that facilitates quick installation, disassembly and reconfiguration to accommodate the changing needs of different storage layouts. The unique flexible connectors connect the bollards to the beams while also allowing for a variety of combinations.

- Sustainability and Social Responsibility

With excellent impact and aging resistance, flexible barriers are able to maintain functional stability for a long time in high-intensity use environments such as warehouses and plants. The extended service life means less replacement needs, which decreases the environmental impact during production, transportation and installation, and creates a safer and more efficient working environment for employees.

Application scenarios

Flexible barriers are suitable for a variety of scenarios:

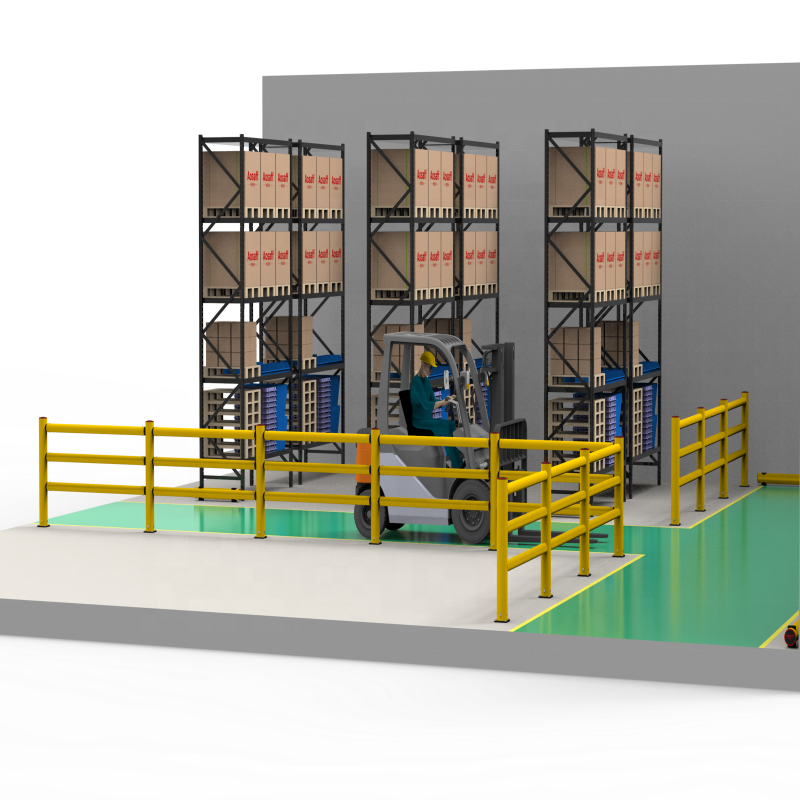

Warehousing & logistics centers: For dividing the pedestrian and vehicle channels to prevent forklift impact accidents.

Workshop: To protect equipment from accidental impacts and ensure smooth production.

Parking and loading areas: Reduce the risk of vehicle collisions.

......

In these areas, where forklifts, automated equipment and foot traffic are dense, collisions are a higher risk. Flexible barrier can effectively separate human and vehicle, to protect the racking system and equipment, and improve the overall safety of the working environment.

“Safety is an investment, not a cost.” Choosing flexible barriers is undoubtedly a critical step toward ensuring workplace safety and sustainable development. With growing emphasis on workplace safety, the demand for flexible barriers in the market is expected to rise steadily.

Learn more about Aotto's safety products: machine guarding fence, ground barrier, bollards

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.