Top 5 Features of a Reliable Industrial Robotic Tool Changer | Aotto 2025 Guide

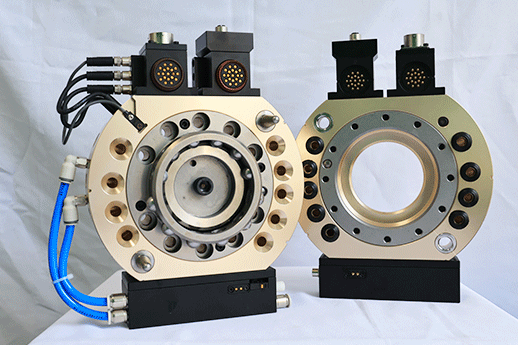

Industrial robotic tool changers help machines switch tools quickly and safely. But not all tool changers are the same. Let’s break down the 5 most important features to check before buying one.

1. Capacity: Don’t Overload Your Robot

Why It Matters: Industrial robotic tool changers aren’t just accessories – they’re productivity multipliers.

Aotto’s Solution: 6kg to 700kg payload options, compatible with mainstream industrial robots.

2. Precision: Hit the Same Spot Every Time

Imagine a robot welding car parts. If the tool shifts even slightly, the weld will fail. High-quality tool changers like Aotto guarantee positioning accuracy within ±0.01 - 0.025mm!

3. Durability: Survive Tough Conditions

With the German INGUN probe, Aotto's tool changer can still guarantee accuracy after 1 million changes.

4. Safety: Stop Accidents Before They Happen

If something goes wrong, the tool changer should disconnect instantly. Aotto tool changers are equipped with interlocking functions and support interlocking of the tool release with the docking station.

5. Support: Get Help When You Need It

Even the best tools can have issues. Aotto engineers can remotely diagnose problems and guide your team through fixes via video call.

Free Expert Resources

Download: Tool Changer Catalogue

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.